Northern Smelters under new ownership

Antimony (pure)

Ingots are approx. 20kg. Smaller quantities are sold by breaking the large ingots into chunks. To alloy this properly, a temperature of 630 degrees C is needed. For this reason home hobbyists and shooters find it easier to use antimony already alloyed with either tin or lead.

NOT CURRENTLY AVAILABLE

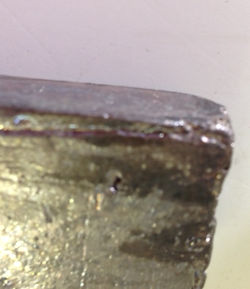

Bismuth

Bismuth is available in slabs of approximately 15kg. This is a necessary component of the low-melting or fusible alloys.

Small quantities are available as chunks broken from the slab.

Bismuth has become popular for making bismuth crystals as seen on videos on internet. It can be remelted and cast again, so often just 500 grams or 1 kg is enough for this purpose.

Bismuth has the unusual property of expanding as it cools.

NOT CURRENTLY AVAILABLE

Cadmium

This is available for electroplating in balls of approx. 600 grams each.

Lead

Ingots: Available in 25kg or 5kg ingots (approx)

Sheet lead: Available in widths from 150mm to 1200mm and thicknesses from 0.5 mm to 2.65 mm. Contact us with your specific request.

Lead Shot: New lead shot in a range of sizes in 10 and 25 kg bags .

Lead Slabs: Cast to order in a range of sizes. Uses are in radiation shielding, weights, or for use in leatherworking.

Tin - High Purity

All tin supplied by Hayes Metals meets industry standards, and is available if required with a Certificate of Analysis. Every batch of tin used by Hayes Metals Pty Ltd is sampled, and tested by an independent NATA approved laboratory to confirm quality of all material we supply.

Ingots – approximately 25 kg

Bars – approximately 3kg

Sticks – approximately 500gm or 750gmPellets – 23 grams - used in electroplating baskets, or for small additions of tin in foundries

Pellets – 23 grams - used in electroplating baskets, or small additions of tin in foundries

*Contrary to common usage of the word, ‘tin’ is NOT used for tin cans, roofs or sheds! The mis-use of the word stems from 'tinned cans' and other applications of tin, where tin's properties of protecting food from contamination and iron from rusting have been valuable. 'Tin' roofs and sheds are zinc-coated steel - i.e. galvanised iron or zincalume!

Tin is a beautiful lustrous white metal, 'silvery' in appearance. It oxidises to a soft dull grey (not black like sterling silver!), If it becomes dull it can be polished again to a bright 'silvery' colour. It is the most expensive of the 'base' metals, approximately three times the value of copper and ten times the value of lead.

Tin is low-melting and malleable. This property allows it to be beaten to give an attractive patina, but to make it hard enough for most practical uses it needs to be hardened by small additions of other metals. In the past, lead was sometimes used for this purpose, but the modern standards we apply strictly exclude lead in our pewter.